BEAD & BABA Compliance Guide: What Broadband Providers Need to Know for U.S. Infrastructure Projects

14th Apr 2025

Introduction

Both BABA and BAA aim to support domestic manufacturing. BABA represents a significant expansion of "Buy America" requirements, applying to a broader range of projects and imposing stricter domestic content rules for infrastructure-related federal financial assistance programs.

| Aspect | BABA (Build America, Buy America Act) | BAA (Buy American Act) |

|---|---|---|

| Purpose | Ensures federally funded infrastructure projects use domestically produced materials. | Requires U.S. government purchases to favor American-made goods. |

| Scope | Focuses on infrastructure projects funded by federal financial assistance. | Covers federal procurement of goods, supplies, and materials. |

| Material Coverage | Applies to construction materials, iron, steel, manufactured products, and others. | Applies to materials and manufactured goods for government use. |

| Enforcement | Agencies are required to implement and enforce compliance with Buy America standards. | Compliance is monitored through federal procurement rules and audits. |

| Legal Framework | Established under the Infrastructure Investment and Jobs Act (2021). | Originally established under the Buy American Act (1933). |

| International Agreements | Typically stricter and less flexible for international trade exemptions. | Allows for exemptions under trade agreements like WTO GPA and FTAs. |

| Application Period | Effective for projects post-2021 under the Infrastructure Investment and Jobs Act. | Long-standing regulation since 1933, with amendments over time. |

BEAD program recipients and sub-recipients are responsible for compliance with BABA. Compliance should be met before the product is installed or used in the project.

Specific standards must be met to ensure products are manufactured in the United States. For iron and steel goods, the entire manufacturing process, from melting to applying coatings, must happen in the U.S. For other manufactured products, there are two main requirements. First, the product must be made in the United States. Second, more than 55 percent of the total cost of its components must come from parts that are mined, produced, or made in the U.S. There may be exceptions if other standards are already in place that meet or exceed this percentage. The same rule applies to construction materials: all manufacturing stages must take place in the United States. Software costs, R&D expenses, and labor costs are not included in this calculation.

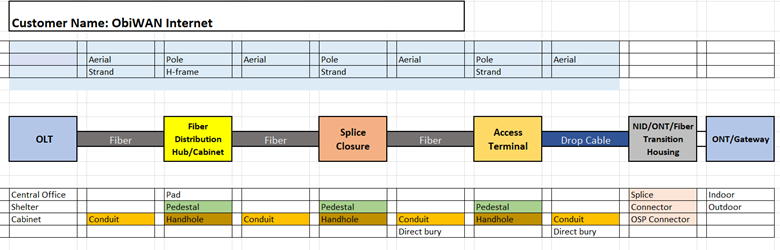

Network Diagram

Exemptions

Under BABA Section 70914, the Department of Commerce (DOC) can waive the requirement to use domestic materials in specific cases. This can happen if applying the preference is not in the public interest, the materials are unavailable in the U.S. in sufficient quality or quantity, or using domestic materials would increase project costs by over 25 percent.

Tools

Tools and equipment used to perform construction activities for a BEAD Project do not need to be BABA compliant. A Buy America preference only applies to articles consumed, incorporated, or affixed to an infrastructure project.

The Department of Commerce (DOC) indicates that spending on optical fiber and fiber optic cable may surpass investments in other equipment for the Tribal Broadband Connectivity Program (TBCP). To ensure a consistent supply of compliant materials, DOC proposes waiving the Buy America Preference for certain non-optic-glass components used in optical fiber production. This waiver specifically allows fiber optic cable connectors to be manufactured outside the U.S. and adheres to standards established by the Office of Management and Budget (OMB). Additionally, the National Telecommunications and Information Administration (NTIA) also seeks to waive the Buy America Preference for unrepeated submarine fiber optic cable, citing a lack of domestic supply for some tribal projects. However, cable assemblies should be made with BABA-compliant cable.

Electronic manufactured products

The Buy America Preference may be waived for most electronic equipment, including combined ONTs/ONUs, residential gateways, and other similar devices.

Passive Optical Equipment

Most passive optical equipment, including splitters, multiplexers, demultiplexers, taps, directional couplers, connectors, optical filters, attenuators, and wave division multiplexers, is manufactured overseas. This equipment category represents a small percentage of total network spending. As a result, the Department of Commerce (DOC) proposes waiving the Buy America Preference for passive optical equipment.

BABA Scope

Electronic manufactured products

The NTIA is looking to waive the Buy America Preference requirements for all electronic manufactured products, albeit with a few exceptions. Certain items may still need to be produced in the United States, but 55% of their component costs won't have to originate from the USA.

- OLT (Optical Line Terminal), Remote OLT, OLT Line Cards

- Subscriber-facing Pluggable Optical Transceivers

- Standalone ONTs (Optical Network Terminals)/ONUs (Optical Network Units)

- Combined ONTs that function only as a standalone ONT/ONU (e.g., a combined ONT/router with the routing functionality disabled)

Iron or Steel Products

The Buy America Preference is not waived for any iron or steel products used in TBCP-funded broadband projects, including radio towers for terrestrial fixed wireless deployments.

Pluggable Optical Transceivers

Regarding Pluggable Optical Transceivers, whether sold independently or installed in an OLT the following manufacturing process, at a minimum, must be conducted entirely within the United States:

- Optical sub-assembly installation.

- Housing assembly.

- Software integration (including firmware integration, installation of licensed software, and customer-specific configuration

- Testing and quality assurance.

- Packaging and shipping.

Enclosures

The Department of Commerce (DOC) may not allow a waiver for the 55 percent cost requirement on components in cabinets, vaults, pedestals, closures, and terminals. However, DOC recommends evaluating enclosures independently to determine if they comply with the Buy America Preference. Construction materials or products packaged with an enclosure must also be checked for compliance with Buy America requirements.

Other Network Equipment

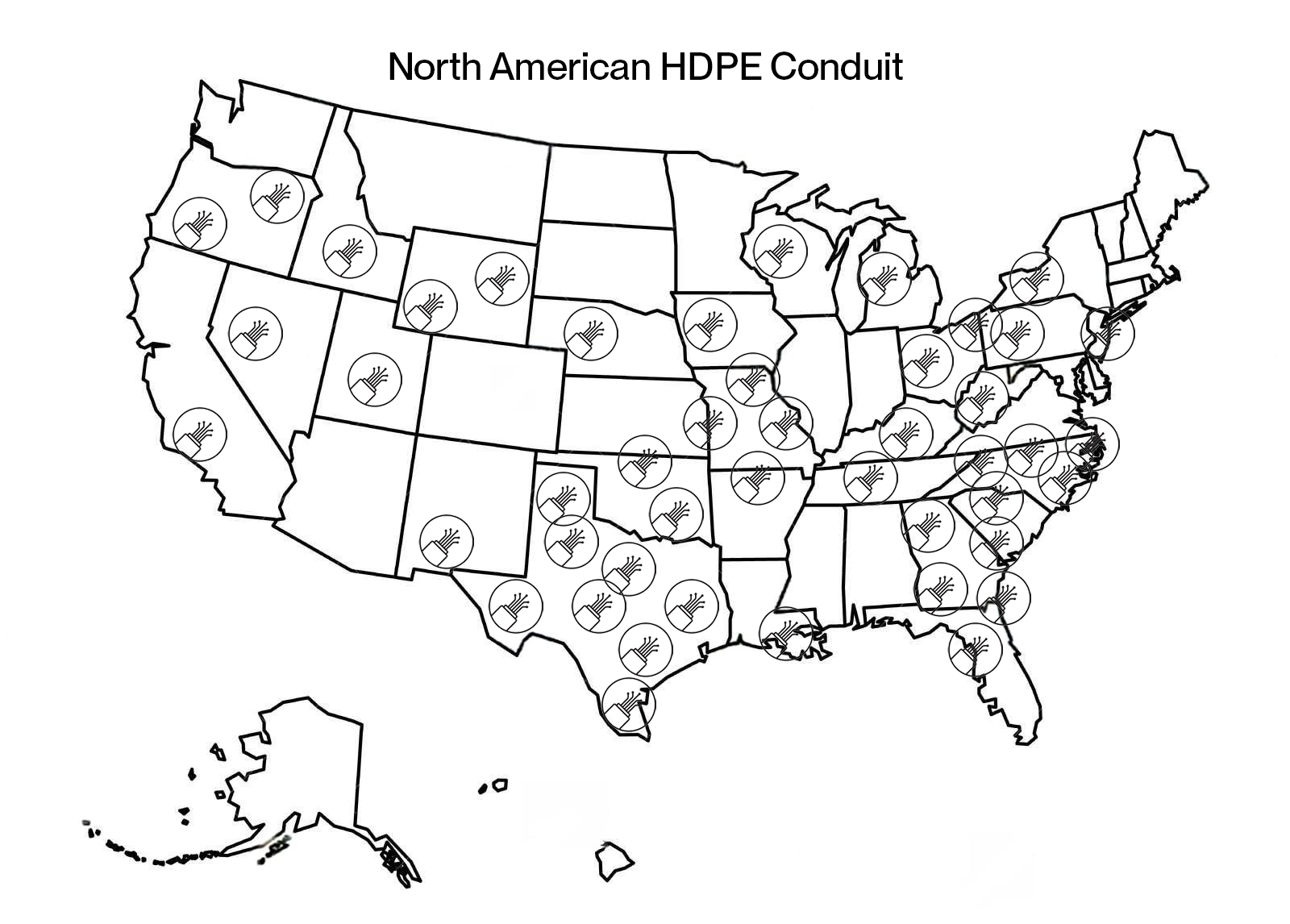

Non-electronic network equipment, such as conduit, mounting brackets, and patch panels, represents a small portion of overall network costs, is domestically manufactured, and is relatively low-cost.

The DOC also asserts that the value of minor hardware items typically won’t exceed the waiver limits. Moreover, recipients of the Broadband Infrastructure Investment Program (TBCP NOFO) are required to make a good-faith effort to track and report the quantity and value of these minor hardware items used in their projects.

Domestic Gaps

Aerial

- Pole Line Hardware (Maclean, Allied Bolt, Hubble)

- Clamp Assemblies of bolts, washers, anchors, bolts, forged pieces

- Tap Bracket for FO slack storage unit

- Drop line Hardware

- Capacity constraint for Strand wire. Make sure you have plans to stay ahead with lead times of 3-10 weeks

- Biggest capacity gap lashing wire

- Plastic version: FORTE plastic, ABB

- Metal version: central wire

- Banding – risk if there is a shortage of stainless steel on the market

Handhole

There is significant production in Mexico, but also a lot of production in the US.

Tiers rated for the market HDPE and polymer concrete are coming more and more every day in the US.

Vaults and Other Below Ground Housings (Vaults)

When choosing underground materials like vaults, it's important to remain flexible with your technology, whether that involves using HDPE or polymer concrete, especially when faced with limitations. We recommend getting both materials approved to help you effectively address any challenges that may arise.

Pedestals and Other Above-Ground Housings (Pedestals)

The bracket tree inside the pedestal may be a gap.

As the BEAD Program continues to drive historic investment in broadband infrastructure, understanding and adhering to the Build America, Buy America requirements is crucial for all stakeholders. While certain waivers provide flexibility in sourcing components that are not readily available domestically, the overall goal remains clear: strengthen U.S. manufacturing and ensure long-term sustainability in our nation’s broadband networks. By staying informed, planning ahead, and working closely with suppliers, BEAD recipients and sub-recipients can navigate compliance confidently and contribute to the broader mission of closing the digital divide.

Contact us to learn more about how Netceed can support your BEAD and BABA needs.

Disclaimer

This information is provided at no cost to participants in the BEAD Program. While we strive for accuracy, Netceed cannot guarantee the completeness or correctness of the information provided and is not responsible for any issues that may arise from its use. It is important to exercise caution, as reliance on this information for any purpose is not advised. If you choose to share this information with others, please ensure they are aware of this disclaimer. Netceed will not be held liable for any consequences resulting from the use of this information.

Definitions

The BEAD funding program, part of the Bipartisan Infrastructure Law, allocates $42 billion for building high-speed internet networks. Its goal is to connect all Americans, especially those in areas with no internet access or slow speeds (under 25/3 Mbps) and those with limited access (below 100/20 Mbps). It supports infrastructure deployment, mapping, and adoption. This includes planning and capacity-building in state offices.

The National Telecommunications and Information Administration (NTIA) is part of the Department of Commerce. It helps the President with decisions about telecommunications and information policy.

The Build America Buy America Act is part of President Biden’s Bipartisan Infrastructure Law. It requires that materials for government-funded construction projects, like roads and bridges, come from the United States. This includes iron, steel, and other manufactured products, as well as various construction materials. The Act was enacted on November 15, 2021, as part of the Infrastructure Investment and Jobs Act. Starting May 14, 2022, all iron, steel, manufactured products, and construction materials used in federally funded infrastructure projects must be manufactured in the United States.